Explore Our Products

EIS Approach

At EIS we provide engineered solutions to your needs. Our process starts and ends with you and your unique environment. While many machines builders will try to steer you towards a standard solution, our process is determined by taking a fresh approach to your production needs and may lead to an entirely unique solution. Our process includes the following steps:

We begin with a thorough understanding of your unique business needs. We look carefully at your current processes, constraints, and goals. We start by envisioning the ideal solution to your production needs, and work with you step by step to provide a tailored solution.

Our engineering department is comprised of experts in machine design and factory automation. Our staff has extensive experience in mechanical engineering, hydraulic and pneumatic design, electrical engineering and controls design, and PLC and HMI programming. Our sales team are also engineers, and work closely with our design and production team while providing customers a single point of contact.

We leverage our in-house machine shop and purchasing department to ensure an exact replacement to address your spare parts needs. If onsite service is required, we send the same team that built the equipment in the first place.

01. SOLUTION DEVELOPMENT

02. Design

Our engineering department is comprised of experts in machine design and factory automation. Our staff has extensive experience in mechanical engineering, hydraulic and pneumatic design, electrical engineering and controls design, and PLC and HMI programming. Our sales team are also engineers, and work closely with our design and production team while providing customers a single point of contact.

03. Build

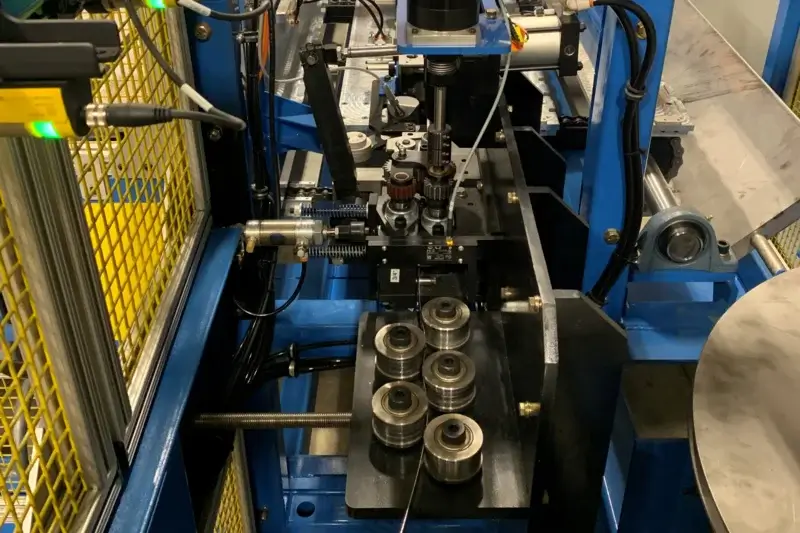

Our manufacturing is done in-house and on-site: Our shop handles raw material cutting, water jet cutting of metal and plastic, forming, machining, welding, assembly, electrical wiring, control panel build, painting, packing and shipping, and much more are all done within our shop. Factory acceptance testing is also completed onsite. Our facilities in Lafayette, IN and Victor, NY include over 44,000 square ft of design, manufacturing, and testing space.

04. INSTALLATION & COMMISSIONING

Our engineers and technicians supervise our installations worldwide. The same team that designs and builds your equipment handles installation and commissioning.

05. SUPPORT

We leverage our in-house machine shop and purchasing department to ensure an exact replacement to address your spare parts needs. If onsite service is required, we send the same team that built the equipment in the first place.

Engineering & Industrial Services, LLC (now EIS Machine) started in 1977 designing and building downstream extrusion equipment for the automotive seal industry.

Reliable Solutions for Every Industrial Challenge

Our team delivers top-quality solutions that enhance both performance and aesthetics. We provide reliable, cost-effective service that keeps your operations running at peak efficiency.

Custom Machine Design

Tailored solutions to meet specific manufacturing needs with high-quality expertise.

Machine Refurbishment

Reliable Custom Machines & Industrial Automation Solutions for Every Industry

With over 45 years of expertise, EIS delivers cost-effective, high-quality solutions tailored to your unique manufacturing needs. Contact us today for a free quote!